Heat pumps are a type of heating and cooling system that are popular for their versatility and efficiency. They’re different than standard air conditioning units, and the term ‘heat pump’ is sometimes used a catch-all for several types of HVAC systems. So, for this post we’ll aim to answer questions like:

What is a Heat Pump?

In short, a heat pump is an HVAC system that uses the refrigerant cycle to provide both heating and cooling functions. These systems work to pump heat either into or away from a space, depending on the mode.

Check out our blog on the components of a standard refrigeration cycle for some more context/background.

But whether a heat pump is being used in a residential, commercial, or large-scale industrial application, its function is the same – "pumping" heat into or away from a space. Moreover, heat pumps are popular, in part, because once that heat is moved out of a space it can be used for functions like heating domestic hot water (DHW) or in-floor hydronic systems. Heat pumps are also used in industrial applications to reduce wasted thermal energy and contribute to improved overall efficiency.

How are Heat Pump Systems Different Than Standard Air Conditioners?

While the two are sometimes used interchangeably, a heat pump and an air conditioner aren’t necessarily the same thing. Both utilize the refrigeration cycle, but in a one-mode A/C unit, the refrigerant only ever travels in one direction. In heat pump systems, that flow is reversible, allowing the system to alternate between heating and cooling functions as needed. But to do so there are some specialized components that a heat pump needs, two examples of which are:

- The reversing valve

- Check valves

The Reversing Valve

For a heat pump to be able to switch between heating and cooling modes, the flow of the system's refrigerant must be reversible. That's where the reversing valve comes in. Also called a four-way valve, the reversing valve diverts refrigerant to the next component in the cycle according to its setting.

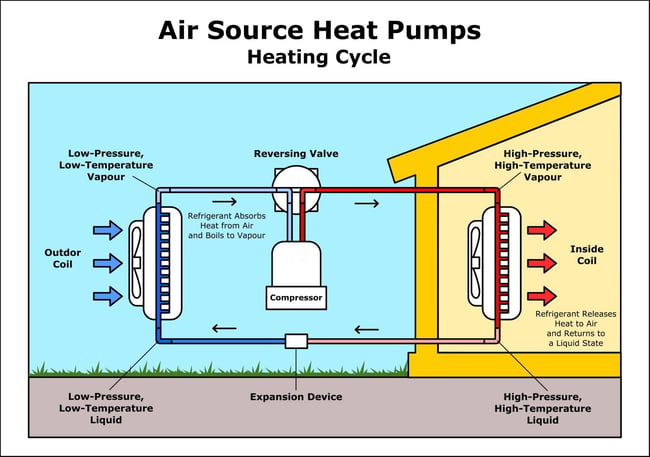

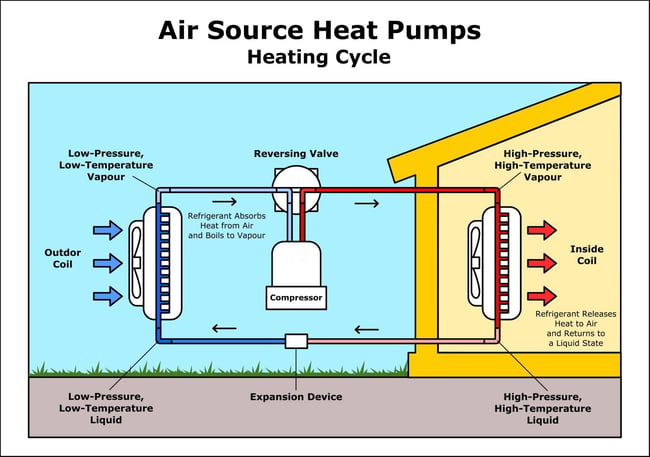

In heating mode, fans blow outside air across the outside coil and the air’s thermal energy is absorbed into the refrigerant within the coil’s tubes. The refrigerant is then sent through the reversing valve, which – because it’s in heating mode – directs the low-pressure gaseous refrigerant to the compressor.

The refrigerant leaves the compressor as a high-pressure, high-temperature vapor. It then goes to the indoor coil, where the cooler air in the space flows across it, which heats the space and condenses the refrigerant to liquid as it does so. The liquid refrigerant then flows to the system’s thermal expansion valve (TXV), where it expands to a gas before being sent across the outdoor coil and restarting the cycle.

In cooling mode, gaseous, high-pressure refrigerant leaves the compressor and enters the reversing valve, which is positioned to divert the refrigerant flow to the outdoor coil. There, heat is expelled from the refrigerant into the ambient environment, condensing the refrigerant to a high-pressure, low-temperature liquid in the process.

Next, the refrigerant heads to the TXV where its pressure and temperature are reduced before entering the indoor coil as a two-phase mixture. The refrigerant’s trip through the indoor coil completes the phase change from liquid to gas as energy from the warmer indoor space is absorbed into the refrigerant and the area is cooled.

Next, the refrigerant is sent back through the reversing valve and into the compressor where the process repeats. In a heat pump’s heating cycle, the indoor coil essentially serves as the system’s condenser and the outdoor coil plays the role of the evaporator.

Reversing valves can range in complexity, but that ‘reversing’ function is the main thing to know about them. An example of a 4-way reversing valve is shown above. A digital-controlled solenoid facilitates its opening and closing. The YouTube channel “The Engineering Mindset” has an excellent video that explains reversing valves in greater detail.

Like what you're reading? Subscribe to our blog and never miss a post!

Check Valves

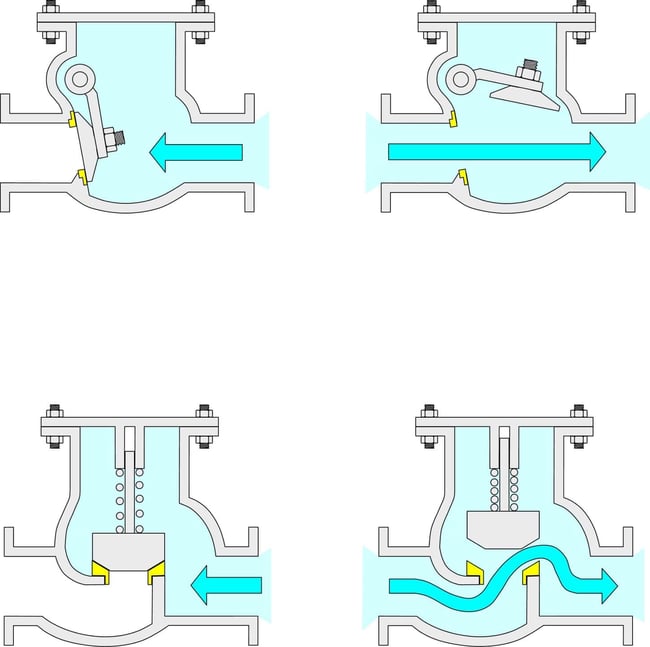

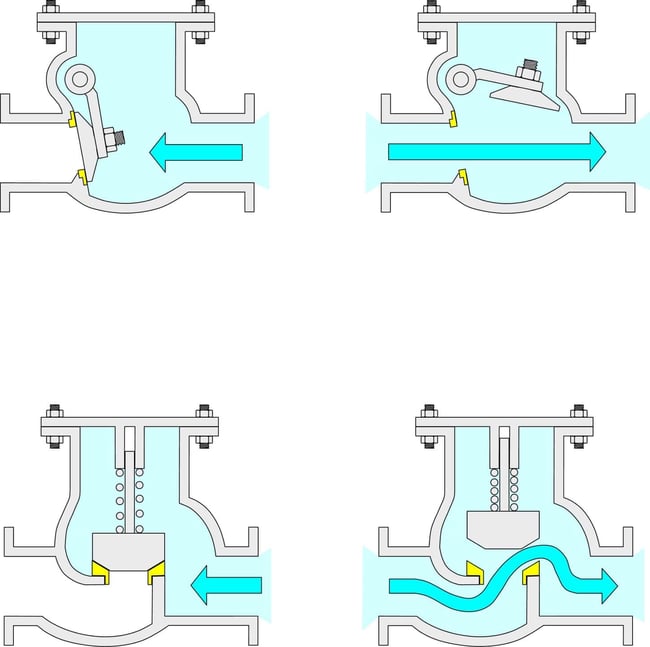

Sometimes heat pump systems have two TXVs; one used in heating mode and the other for cooling. To ensure the refrigerant only passes through one of them, the check valve works like a railroad switch, directing refrigerant either through the TXV or bypassing it depending on the mode. Two examples of check valves are pictured below: A swing check valve (top) and a spring-loaded variety.

What are Some Different Types of Heat Pumps?

Now that we’ve covered what heat pumps are and some of their unique components, let’s talk about some common varieties. There are several kinds of heat pump systems, all of which execute the same functions, but in different ways. Some of the more common configurations are:

- Air to air heat pumps

- Air to water heat pumps

- Geothermal heat pumps

Air to Air Heat Pumps

Also called air source heat pumps, air to air heat pump systems have a very simple design. They take in outside air and, using the standard refrigeration cycle, condition that air to either cool or heat a space.

Air to air heat pumps are very popular for residential and small commercial applications in moderate climates due to their efficiency and versatility. It’s likely these are the kinds of systems that come to mind when you hear “heat pump,” and it’s quite possible that your home features something similar. The diagram above shows a typical residential heat pump system and the picture below is a commercial heat pump at an apartment building.

Air to Water Heat Pumps

Air to water heat pump systems function in a manner very similar to their air-to-air counterparts. But, instead of drawing in heat from the outside air to heat an airstream, air to water heat pumps use the refrigeration cycle to manipulate the temperature of a fluid stream.

In heating mode, thermal energy is extracted from the cool outside air through the standard compression/expansion of a refrigerant and transferred to a fluid stream - usually water or a glycol/water mix. That hot water is then routed throughout the building where it's used for space heating, domestic hot water, or some other useful function. That process in inverted when in cooling mode, with thermal energy transferring from the outside air into a fluid stream, which is chilled via the refrigeration cycle and the absorbed heat is expelled outside.

Geothermal Heat Pumps

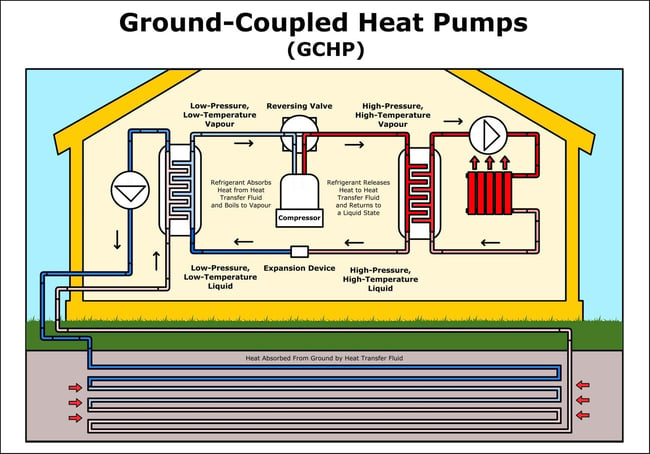

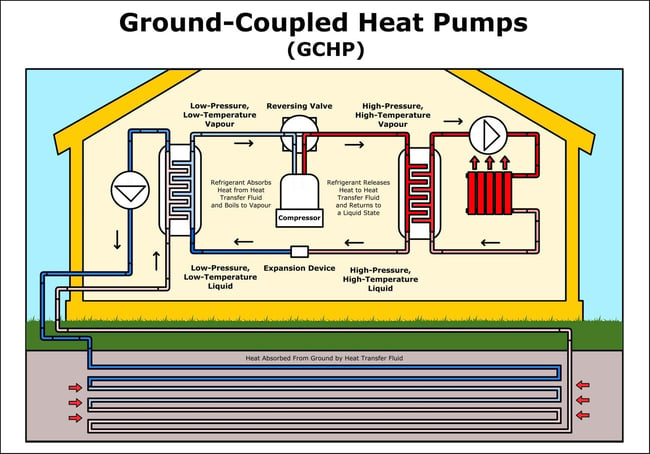

At depths greater than 15-20 feet, the earth's crust maintains a fairly consistent temperature year-round. Ground source heat pumps (GSHPs) – also known as ground-coupled heat pumps or geothermal heat pumps – are closed-loop systems that make use of that thermal energy.

GSHPs feature a heat exchanger (or geo loop) buried within the earth like in the diagram below and connected to the rest of the heat pump's components located inside the structure. A propylene glycol solution is often used as the working fluid because of its lesser impact on the environment compared to ethylene glycol.

In heating mode, thermal energy from the earth is absorbed into the fluid within the geo loop. This increases the working fluid's temperature, but not enough to meet the load requirement. The semi-heated fluid mixture is then sent inside to the system's evaporator, kick starting the vapor compression/expansion cycle, which heats the fluid to the point that it can be used to heat space or water.

In cooling mode, warm air from the structure is sent through the geo loop where the earth’s cooler temperatures condition the fluid before returning it to indoor heat pump. There, the refrigeration cycle is used to extract the remaining energy needed to meet the system requirement. The geo loop can be buried in the ground, submerged in ground water, or connected to a well or some other water source. Geothermal heat pumps that involve water are often referred to as water source heat pumps, but the system function and componentry are the same.

While geothermal heat pumps come with quite a bit of upfront cost, they’re remarkably efficient once installed. It’s not uncommon for such systems to output significantly more energy than is put into them, with coefficients of performance (COPs) as high as 4:1 being fairly typical.

How Super Radiator Coils Can Help

Heat pumps have benefitted from some tremendous innovation over the last few decades. And the advantages of these high-efficiency systems are some of the most diverse out there, capable of effectively serving a range of applications from light commercial to industrial. And if you’re a heat pump manufacturer looking for an expert coil partner to help you push the efficiency envelope, feel free to reach out.

Our heat pump experience runs deep and our database of refrigerant performance information is as comprehensive as they come. From standard heat pump refrigerants like R-410 to more uncommon ones like CO2, let’s work together to maximize the efficiency of your units.

Don’t get left out in the cold when it comes to heat transfer information. To stay up to date on a variety of topics on the subject, subscribe to The Super Blog, our technical blog, Doctor's Orders, and follow us on LinkedIn, Twitter, and YouTube.