Our Refrigerant Focus series delves into the history, properties, suitable applications, and pros and cons of some of today’s popular or otherwise noteworthy refrigerants. This installment will focus on R-1234ze.

Check out some of our refrigerant focus posts below.

History

R-1234ze (scientific name 1,3,3,3-tetrafluoropropene) is known as a “next-gen” refrigerant. Next-gen refrigerants are a group of substances that includes refrigerants like R-32 and R-1234ze’s HFO brother, R-1234yf. These refrigerants all share a common trait: a fractional global warming potential (GWP) than that of their synthetic predecessors.

Most next-gen refrigerants, including R-1234ze, were developed to be long-term, sustainable replacements for environmentally harmful substances that are being regulated out of production. R-1234ze was developed and patented by Honeywell and designed as a replacement for R-134a.

Properties of R-1234ze

R-1234ze is classified as a hydrofluoroolefin (HFO), which is a class of unsaturated organic compounds made from a combination of hydrogen, carbon, and fluorine. The most notable property of R-1234ze – and HFOs more broadly – is their extremely low impact on the environment.

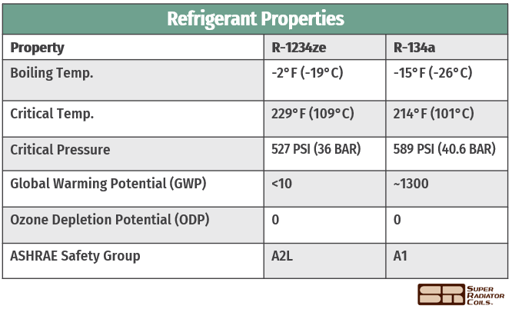

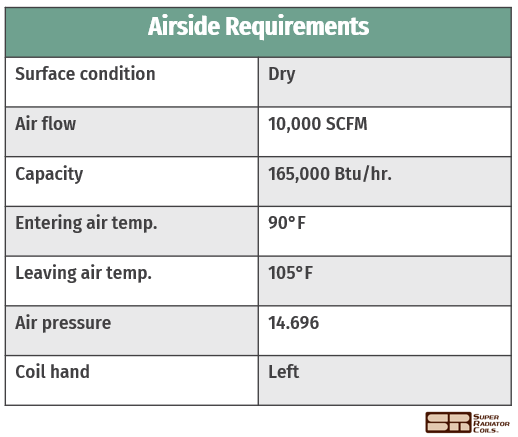

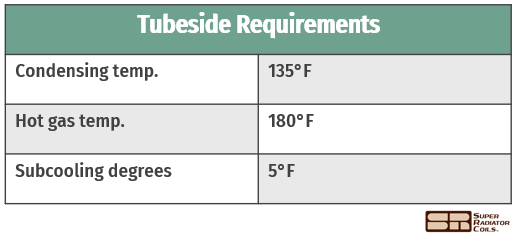

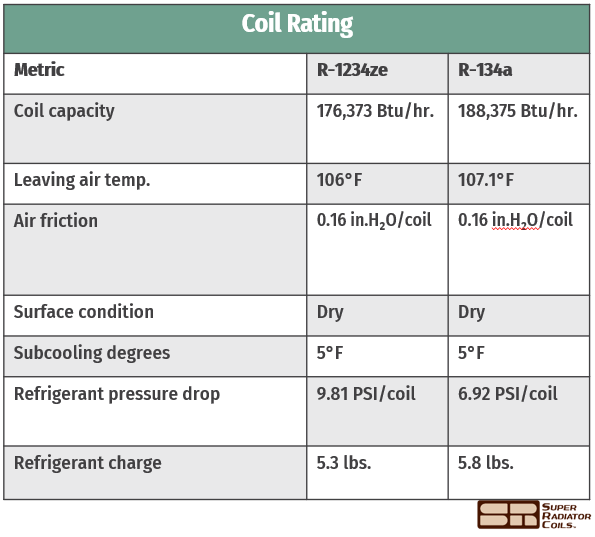

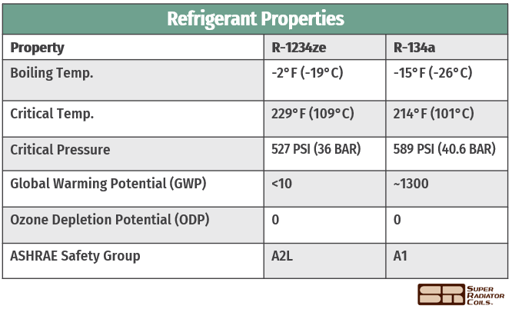

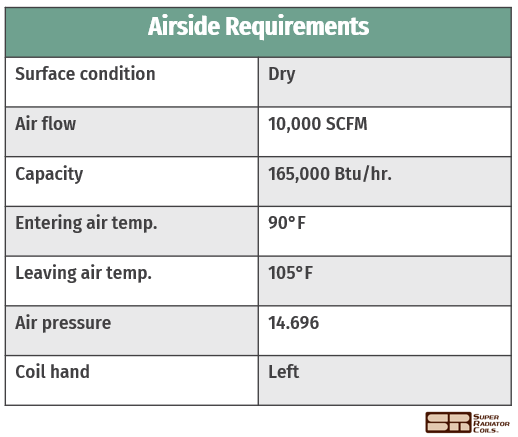

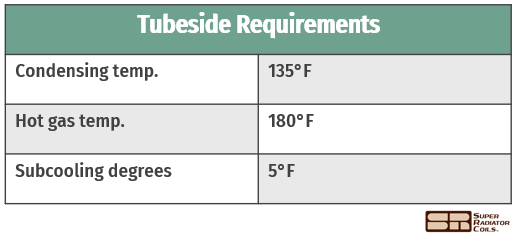

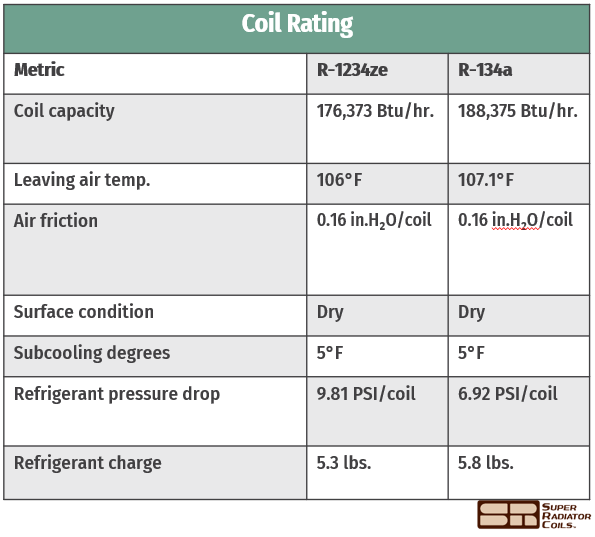

With a GWP somewhere between two and ten, R-1234ze is of significant interest to the engineering and scientific community for its potential as a low-GWP refrigerant. For a performance comparison, we’ve run a theoretical 36” x 70” 2-row condenser through our coil selection software, Enterprise. The coil’s airside and tube-side requirements are below and the coil’s rating is below that. We’ve included a rating for the same coil running R-134a as well.

It should also be noted that R-1234ze is not miscible with mineral oil. Ester-based synthetic lubricant will need to be used in compressors.

Applications for R-1234ze

R-1234ze: Pros

- Low GWP: The primary benefit of R-1234ze is its low GWP and the resulting compliance with the latest environmental regulations.

- Less refrigerant required: As illustrated in the above table, an R-1234ze condenser coil requires about 9% less refrigerant than an R-134a coil at the rated condition.

R-1234ze: Cons

- Lower thermal capacity than R-134a: R-134a is able to absorb and release more heat than R-1234ze.

- ASHRAE classification of A2L: R-1234ze is classified by ASHRAE as somewhat flammable. It can therefore not be retrofitted to R-134s systems, although R-1234ze’s flammability relative to other A2L substances is less black and white.

Honeywell claims that for R-1234ze to become flammable, it would need “10 times more concentration and 250,000 times more energy” than a hydrocarbon refrigerant. And even that couldn’t occur at temperatures lower than 86°F (30°C). This trait has led ASTM International to classify R-1234ze as non-flammable in the context of handling or storage.

Are you considering R-1234ze for your equipment? Give us a call if you have any questions on performance or register for our selection software, Enterprise and select R-1234ze as your refrigerant. From there, you can iterate on design conditions, materials, and more to find what best meets the needs of your requirement.

Don’t get left out in the cold when it comes to heat transfer information. To stay up to date on a variety of topics on the subject, subscribe to The Super Blog, our technical blog, Doctor's Orders, and follow us on LinkedIn, Twitter, and YouTube.