The US started limiting HFC usage on January 1st, 2022, following the passage of the American Innovation in Manufacturing (AIM) Act of December 2020. Prior to the legislation, the EPA did not have the authority to make changes to HFC usage, and HFC policy decisions fell largely to the states, 11 of which had already begun HFC phasedown measures under the US Climate Alliance. The EPA's current phasedown schedule is aiming to reduce the production and consumption of HFCs by 85% below baseline levels gradually by 2036. This means that individuals and organizations that currently use HFCs like R-404A, for example, have a decision to make.

Retrofit vs. New System – How Do I Decide?

Since most equipment manufacturers sell products throughout the country, many have already transitioned to other refrigerants, such as R-290 (propane), R-600A (isobutane), R-448A, or R-449A. But what does that mean for all the R-404A that’s already out there?

Like the R-22 phaseout and R-410A adoption of the early 21st century, R-404A isn’t immediately disappearing. It will be around and available for some time to come, but its impending prohibition is still a critical factor when evaluating refrigerant decisions in the present day. For instance, recharging existing R-404A system with the refrigerant might make sense for minor repair. But what about larger, more involved system repairs? Do you condemn the R-404A system and consider an entirely new system?

Depending on the age of the system and the extent of the required repairs, the answer may very well be “yes.” However, it’s worth noting that individuals or organizations that find themselves asking this question have more options available compared to the change from R-22 to R-410A.

Considerations for Retrofits

System Compatibility

For those that decide to retrofit existing R-404A systems for a newer, less environmentally harmful refrigerant, the new refrigerant should be evaluated with system compatibility in mind.

For example, R-404A systems can be retrofitted with R-449A without too much fuss – needing only a TXV or powerhead changeout, if the powerhead is changeable. Oils are the same for both refrigerants, since both are HFC blends, the system already has POE (or maybe PVE) oil. And not only is a switch from R-404A to R-449A fairly painless with respect to equipment changes elsewhere in the system, it’s also likely more effective from a performance standpoint, too, which we’ll look at in the next section. Like with most system changes, it's best to consult the equipment manufacturer for retrofitting best practices and recommendations.

Chemours, which sells R-449A under the trade name Opteon™ XP40, has a useful guide for R-404-to-R-449A retrofits.

Regulatory Compliance

As we stated earlier, regulation is driving substantial changes in the refrigerant landscape, a fact that must be considered when choosing a refrigerant for your R-404A retrofit or new system. R-507A, R-448A, and R-449A are all mixtures of common HFC refrigerants (some with HFOs also), blended to get the required performance. But, as you can see from the chart below, there is significant variation in their global warming potential. Notice how both R-448A and R-449A have considerably lower GWPs than R404-A.

|

Refrigerant

|

GWP

|

|

R-507A

|

3990

|

|

R-404A

|

3940

|

|

R-407A

|

1910

|

|

R-407F

|

1670

|

|

R-22

|

1810

|

|

R-448A

|

~1300

|

|

R-449A

|

~1400

|

Refrigerant Performance

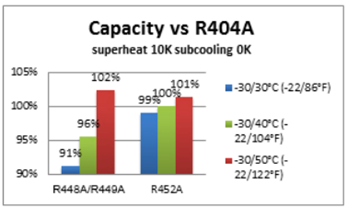

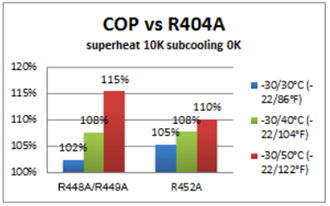

Performance of R-449A vs. R-404A (courtesy of Tecumseh)

While our future may lie with natural refrigerants (CO2, ammonia, propane, etc.), simple retrofits are not possible with those substances. But updating an existing R-404A system with R-448A or R-449A may help customers bridge the gap until a new system with a lower environmental impact system can be installed when doing so is required.

As with all retrofits, do your research and consult with the original system manufacturer for guidelines and suggestions. And if you find yourself in need of a partner to help you better understand the changing refrigerant landscape and its impact on unit and system performance, drop us a line. We can work with you to design equipment that balances performance with existing regulatory requirements and those that may be down the road.

Don’t get left out in the cold when it comes to heat transfer information. To stay up to date on a variety of topics on the subject, subscribe to The Super Blog, our technical blog, Doctor's Orders, and follow us on LinkedIn, Twitter, and YouTube.