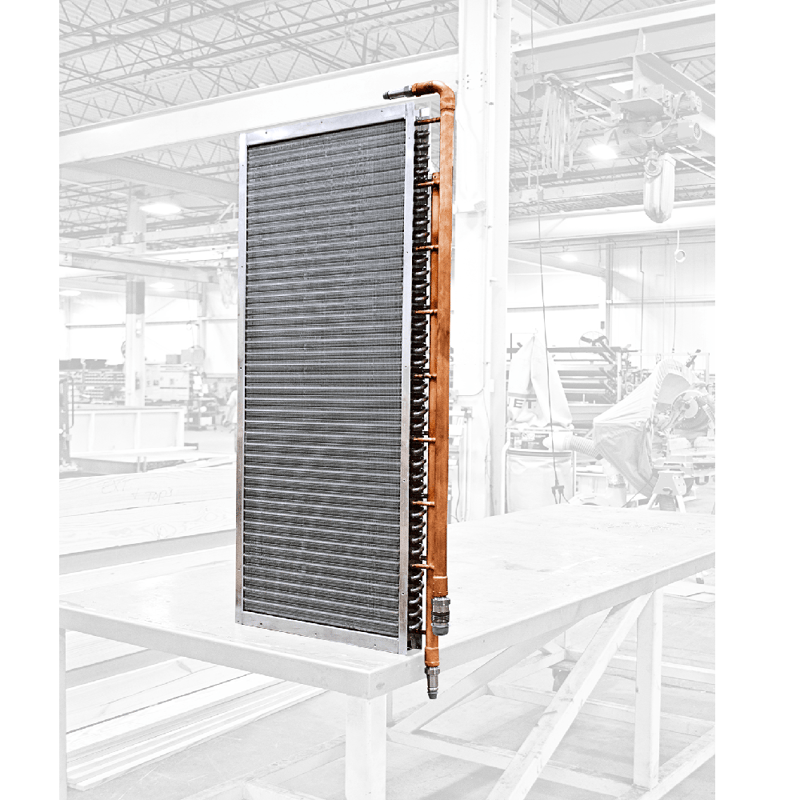

Rear Door Heat Exchangers for Supercomputer Application

These coils are installed in one of the fastest supercomputers in the world – capable of processing 200 quadrillion operations per second – which was designed specifically to support AI-related data needs. This type of application requires maximum heat transfer surface area to increase heat rejection and were therefore designed with 5mm OD tubes and aluminum fins with a raised lance pattern to significantly increase heat transfer performance. They also feature handles and quick connects for easy installation.

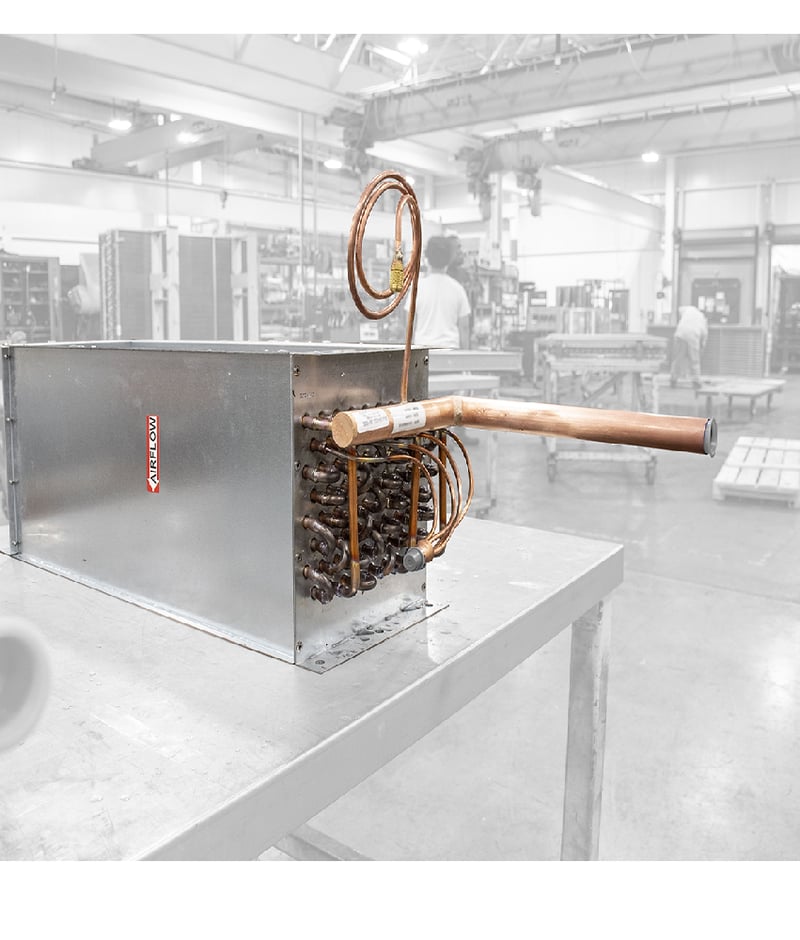

Fluid Coil for Rack-level Cooling Application

This 22" x 23.5", 8-row coil was designed to reject 32 kilowatts of heat away from a server rack. It features 3/8" copper tubes with aluminum fins and included tube extensions to match connection locations within the server cabinet. The coil was designed for a preexisting envelope with very tight spatial tolerances. Return bends and hairpins were required to be inside of the coil's end plates to allow it to fit within the unit.

8-row Evaporator Coil with 3/8” OD Tubes

This coil was used for a post-cooling application in a data center, and was designed for a 21F delta T. The coil was circuited in a thermal counter flow arrangement and has a capacity of 12,215 Btu/hr. This design included a 1/4" x 36" equalizer line that was attached to the suction header.

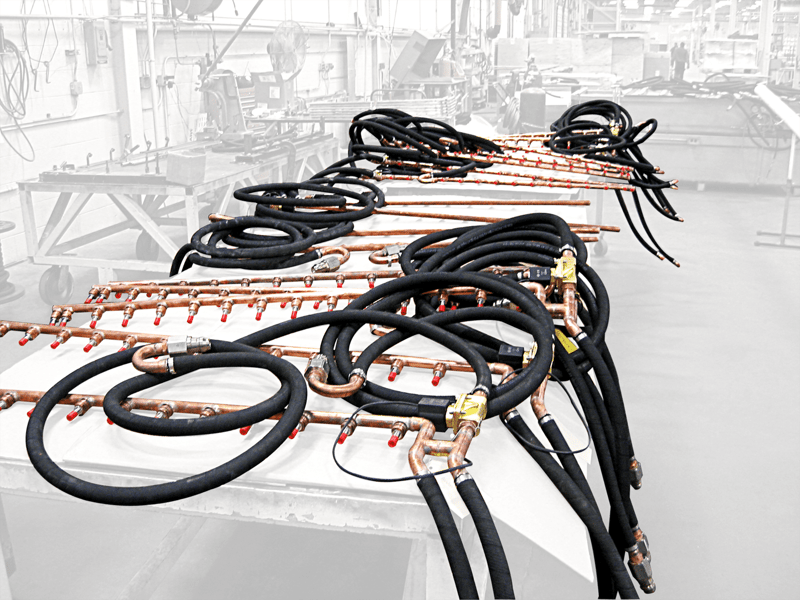

Manifold Piping Assemblies

These manifold assemblies were used to facilitate even cooling distribution to several cooling loops simultaneously. Connections were made of red brass and the project was very high volume, numbering in the hundreds per monthly shipment. The skill of our brazing team was the difference maker for this job, and uniquely positions SRC to take on all manner of this sort of non-standard “coil” work.

Robust Manufacturing Capabilities for a Variety of Applications

200,000+

12

300

Our Process

Initial Design & Prototyping

We’ll learn your performance requirements, spatial constraints, and other application-specific details to develop an initial design and prototype.

Performance Testing & Design Optimization

If desired, we can performance test your coils in our in-house wind tunnel to validate performance ratings based on real-life data, not extrapolations.

Design Finalization & Drafting

Once your design is approved, it’s sent to our design engineering team. It’s one of our largest departments, and that’s by design. Whether you need 100 coils a week or 10 coils per year, our drafting team features nearly 30 mechanical engineering professionals who generate hundreds of designs each month.

Production & Delivery

Your approved final design is released to our manufacturing facility for production. We can flex our production schedules to accommodate fluctuations in production needs. And our dedicated sales support staff will handle purchase orders, billing, etc.

The Importance of Water Quality in Liquid-Cooled Data Center Cooling Systems

Water quality is absolutely critical in high-performance liquid-cooled data center applications. Contaminant-laden water sources lead to fouling, lost performance, and downtime. Read this article to learn more about water quality standards, various definitions of water quality, and filtration considerations.

%20(1).webp?width=442&height=500&name=image%2013%20(1)%20(1).webp)

You’ve got questions. We’ve got answers.

It depends, but setup for unique applications is something we feel we’re very good at. We have a full team of mechanical and industrial engineers who work to optimize our processes, tooling, and scheduling. So, when the time comes, we’re ready to go. Also, our sales engineers are there to support the job from quote to final delivery. Once a design is proven, they’ll work with you to coordinate everything from inspection criteria to delivery schedules, so you get the parts you need when you need them.

We take leaks extremely seriously. If we’re supplying our customers with leaking coils, we haven’t done our job. We offer nitrogen and helium leak testing for “standard” operating pressures, and hydraulic testing for higher pressure applications. When feasible, we like to establish leak testing parameters as part of our quotation/purchasing process. Whether our standard process is sufficient for your application or you need more rigorous methods, we can flex our leak testing protocols to conform with your requirements – down to the molecule.

Cleanliness is critical for data center applications, and we understand that performance reductions from fouled coils or replacement of corroded coils means money lost. All our coils are finished in a citric acid bath to remove any excess braze material, clean joints, and provide an attractive product. Additionally, we offer internal flushing processes to ensure your coils’ internal surfaces start clean and stay clean.