In industries like commercial and industrial HVAC, there’s an understandably massive focus on innovations aimed at improving efficiency. Billions of dollars are spent every year on research and development to drive down operating costs without compromising on performance. Doing more with less is the name of the game, and included among the measures intended to do so is the economizer.

Read More

Topics:

Power Generation,

HVAC,

Heat Exchangers,

Efficiency,

Engineering

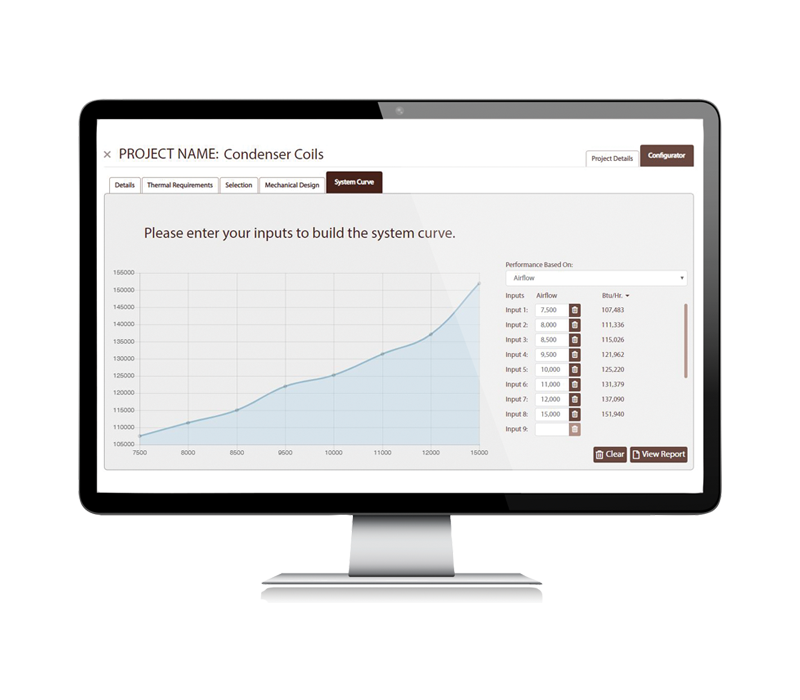

We’re super excited to announce that we’ve validated the performance ratings for R-449A and R-448A condensers in Enterprise, our coil selection software. We believe the condenser coil performance model we’ve developed is the most comprehensive and accurate of its kinds in the industry.

We wanted to use this post to briefly explain our testing methodology to our users. We’ll also touch on why performance modeling for these refrigerants has been challenging in the past, and how we plan to improve our model over time.

Read More

Topics:

Heat Exchangers,

Efficiency,

Expertise,

Reliability,

Engineering,

Refrigerants

There are a number of industrial processes that require extremely cold temperatures – sometimes as cold as -150°F. For the equipment used in such applications, those low temperatures pose some unique challenges. In this post, we’ll detail some of the temperatures involved and outline some things to consider with regard to heat exchanger design and materials for low-temp applications.

Read More

Topics:

Food Storage & Processing,

Coils,

Heat Exchangers,

Expertise,

Reliability,

Engineering

Our refrigerant focus series consists of deep dives into the history, properties, suitable applications and pros and cons of some of today’s common refrigerants. This installment will focus on R-410A.

Read More

Topics:

Refrigerated Display Case,

Heat Exchangers,

Efficiency,

Reliability,

Engineering

Gas-tungsten arc welding (GTAW), or more commonly, Tungsten Inert Gas welding (TIG), is a method of arc welding named for the non-consumable tungsten electrode used during the process. TIG welding isn’t the best option in some industries, but as coil manufacturers, it makes sense for us.

Read More

Topics:

Gas Compression,

Military,

Food Storage & Processing,

Power Generation,

Heat Exchangers,

Nuclear Products,

Expertise,

Quality,

Reliability,

Engineering

This article has been updated. It is accurate as of Feb. 8, 2022

For low-temperature hydronic systems, systems in which chillers and AHUs are located outdoors, or other equipment used in low-temperature processes, some form of glycol is a critical ingredient. It works to lower the fluid’s freezing temperature, enabling lower-temperature operation and preventing freezing.

Read More

Topics:

Food Storage & Processing,

Ground Support,

Coils,

Heat Exchangers,

Efficiency,

Expertise,

Reliability,

Engineering

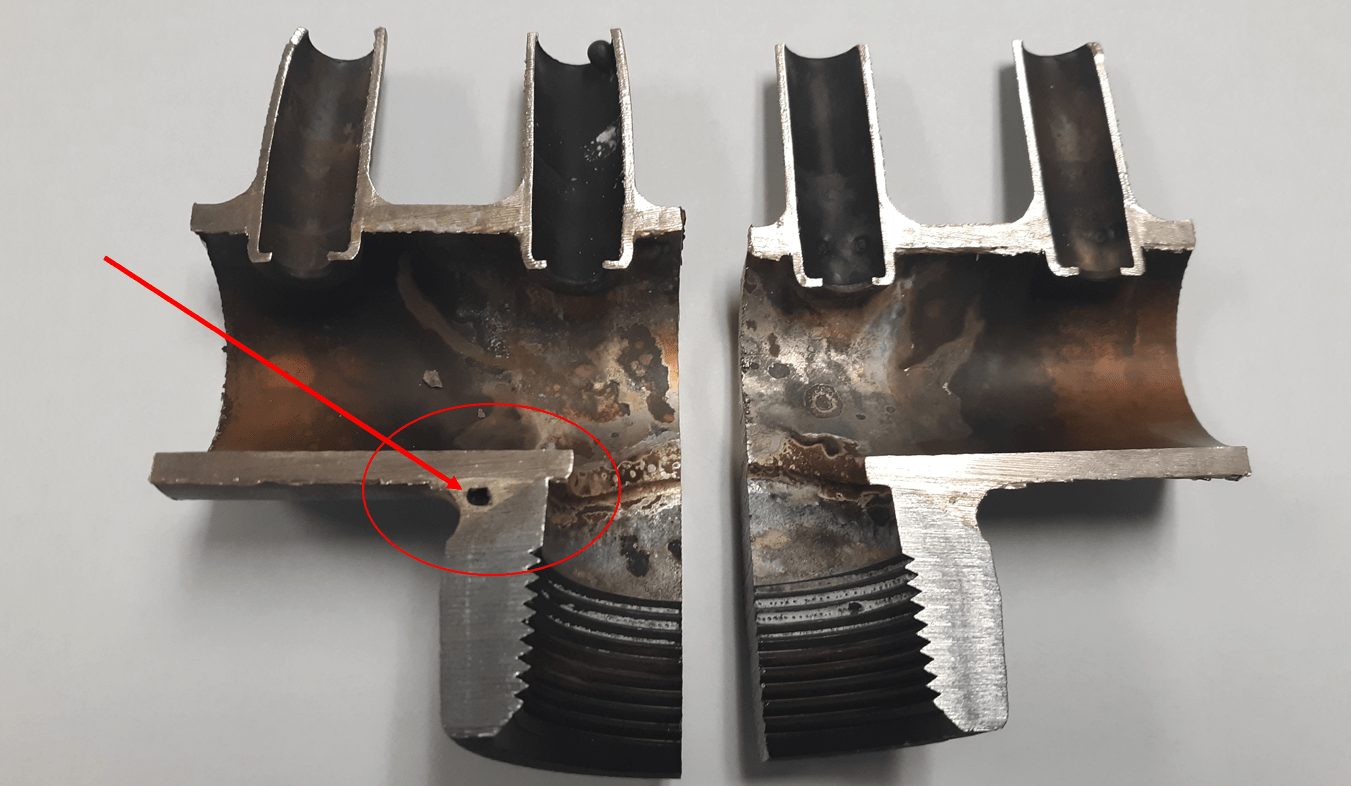

There are terrific braze joints, awful braze joints, and everything in between. Today, we’ll examine one type of defect that can have devastating effects on joint integrity – flux entrapment.

Read More

Topics:

Coils,

Heat Exchangers,

Expertise,

Quality

This article has been updated. It is accurate as of 9/23/20.

Heat exchangers used for different applications need different design features. For example, in industries like pulp and paper, lower fins per inch (FPI) are often included to reduce airside fouling and to make for easier cleaning. Other applications such as the military are often concerned with weight, which impacts material selection. For this post, we're going to focus on some unique design choices we often include when building heat exchangers for the refrigerated storage of potatoes, onions, beets and other vegetables.

Read More

Topics:

Food Storage & Processing,

Coils,

Heat Exchangers,

Quality,

Reliability

In many of the industries we serve, heat exchangers made with copper tubes and aluminum fin are extremely popular, and very often, these materials are a terrific choice. But copper and aluminum aren’t suited for everything. At Super Radiator Coils, the needs of many of our customers often dictate that we explore and understand alternative materials.

Read More

Topics:

Gas Compression,

Military,

Power Generation,

Coils,

Heat Exchangers,

Nuclear Products,

Expertise,

Quality,

Engineering

In fin tube heat exchangers, the fluid (gas/water/glycol/refrigerant/etc.) circulating through the coil’s tubes is extremely important for the coil’s overall performance – it’s half the battle, along with airside heat transfer. The degree to which the fluid contacts the tube walls affects the coil’s performance and influences a system's overall efficiency – the more the fluid comes into contact with the tube wall, the better – and more economical – the heat transfer.

Read More

Topics:

Coils,

Heat Exchangers,

Efficiency,

Engineering