We serve a diverse customer base at Super Radiator, one segment of which are what’s known as original equipment manufacturers (OEMs). Though we classify them together, OEMs and their respective industries all operate differently. Some customers are recurring business – they need coils every week consistently over a given timeframe – we’ve seen this with commercial HVAC or datacenter OEMs. Other customers need us to supply coils for projects that may arise infrequently over a period of years, which describes industries like transit cooling.

Read More

Topics:

Refrigerated Display Case,

Ground Support,

Computer & Electronics Cooling,

HVAC,

Coils,

Efficiency

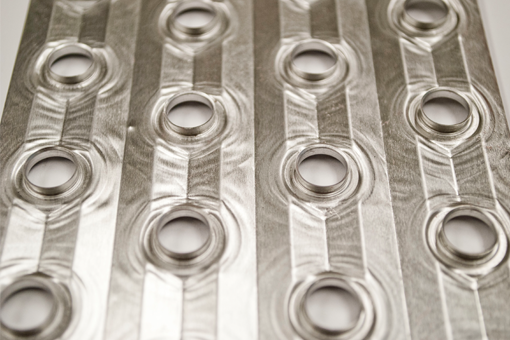

In plate fin heat exchangers, the fins themselves play a critical role. They provide the extended surface area needed to achieve effective heat transfer between a gas on the finside and a fluid on the tubeside.

Read More

Topics:

Gas Compression,

Refrigerated Display Case,

Food Storage & Processing,

Ground Support,

Computer & Electronics Cooling,

Power Generation,

HVAC,

Coils,

Efficiency,

Engineering

It was long thought that a spiral fin design was the only option for use in environments that demanded heavy materials, long life span, and overall sturdiness. Plate fin coils were thought to be too fragile for the rigors of many industrial applications. But over the last few decades, it's become more common to see plate fin style heat exchangers used for a bevy in industrial applications.

Read More

Topics:

Coils,

Heat Exchangers,

Reliability

We get asked a lot of questions about the passivation of stainless steel welds. Oftentimes, customers want to know what passivation is. Others ask if it’s necessary. Given the number of factors that such a decision hinges on, Super Radiator wants customers to understand the benefits of passivation, and also understand what’s involved in the larger process of treating stainless steel surfaces.

Read More

Topics:

Food Storage & Processing,

Power Generation,

Heat Exchangers,

Nuclear Products,

Quality,

Engineering

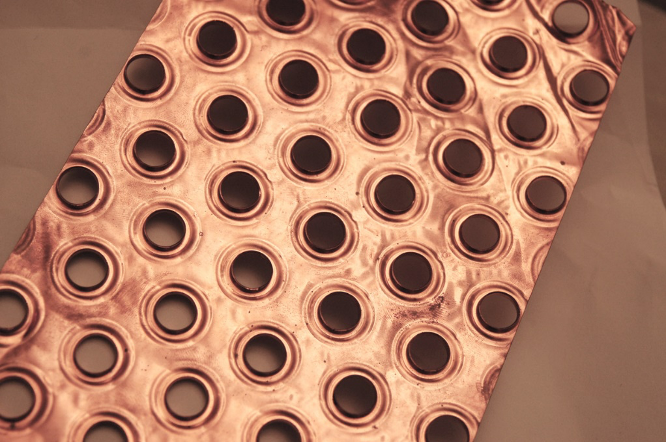

Stainless, copper, E-coat, Heresite, or CuNi?

When Super Radiator Coils engineer coils for customers, materials are among our most important considerations. Things like applications, environments, and coil lifespan must all be factored in to the coil’s design. So too must price and industry standards, making material decisions all the more crucial.

Read More

Topics:

Heat Exchangers,

Expertise,

Quality,

Engineering