When designing a heat exchanger, an engineer should not only consider thermal performance, but also external influences that can negatively impact thermal performance, such as fouling.

Read More

Topics:

Power Generation,

HVAC,

Coils,

Nuclear Products,

Efficiency,

Expertise,

Reliability,

Engineering

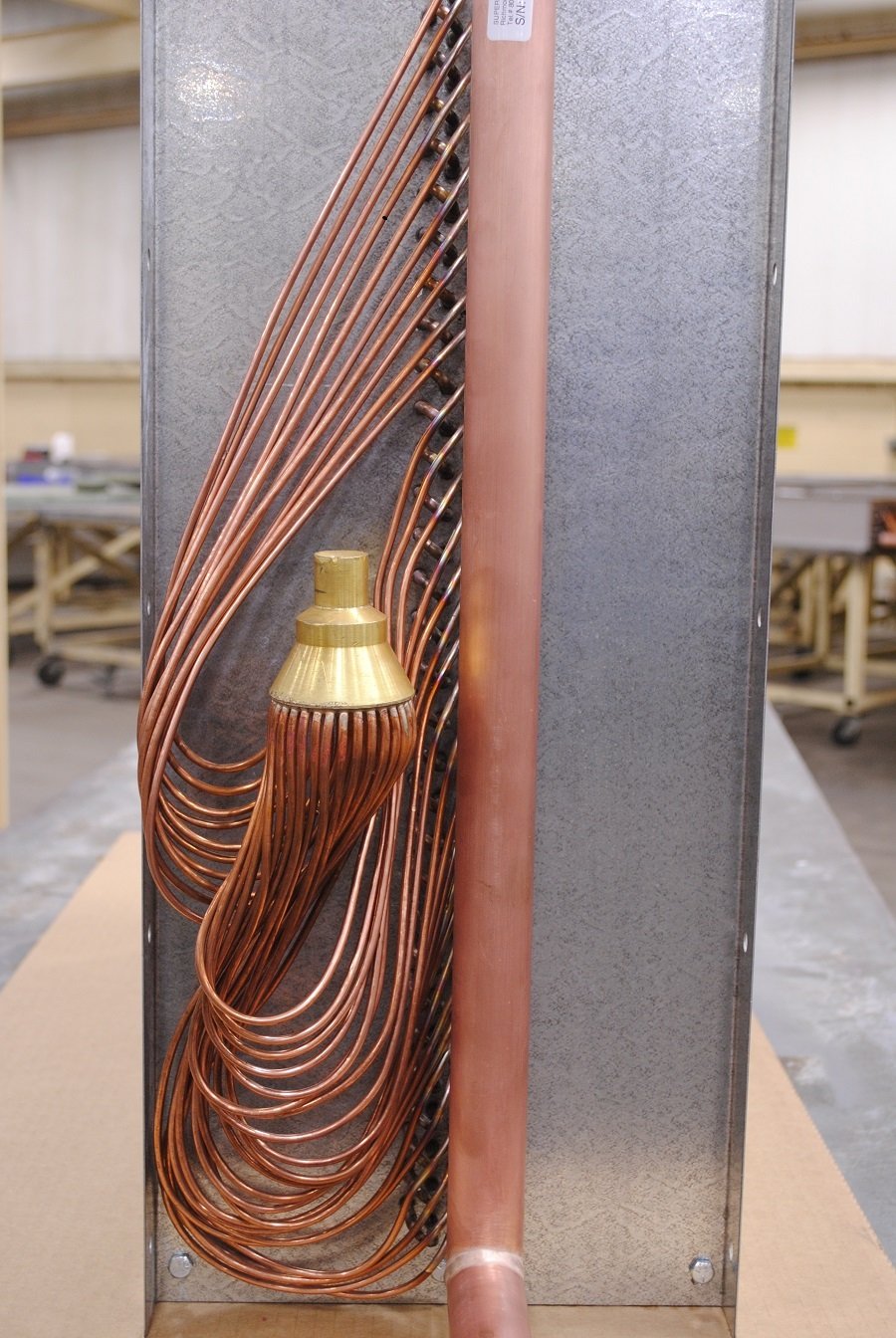

In the heat transfer universe, the term ‘coil’ is typically used to describe lighter duty heat exchangers used for various HVAC-R functions across a slew of industries. However, when the pressures, temperatures, and all-around harshness of an application and installation environment are ratcheted up, this equipment commonly falls under the ‘industrial heat exchanger’ umbrella.

Read More

Gas-tungsten arc welding (GTAW), or more commonly, Tungsten Inert Gas welding (TIG), is a method of arc welding named for the non-consumable tungsten electrode used during the process. TIG welding isn’t the best option in some industries, but as coil manufacturers, it makes sense for us.

Read More

Topics:

Gas Compression,

Military,

Food Storage & Processing,

Power Generation,

Heat Exchangers,

Nuclear Products,

Expertise,

Quality,

Reliability,

Engineering

My parents were fond of saying, “There is only so much meat on the bone.” No matter how hungry we children were, there was a limit as to what meat we could get from gnawing a bone. The same is true for coils. No matter how hard we wish for more, a coil can only transfer a limited amount of heat. Why is that?

Read More

Our Refrigerant Focus series delves into the history, properties, suitable applications, and pros and cons of some of today’s popular or otherwise noteworthy refrigerants. This installment will focus on R-32.

Check out some of our refrigerant focus posts below

Read More

Today, most new air conditioning system components that would have used R-22 prior to its regulation are now designed to operate with R-410A. However, R-22 systems, such as commercial split systems for example, still exist. This means that when a coil reaches the end of its service life, the system engineer has a decision to make: replace the system or convert the existing equipment to operate on R-410A.

Read More

In a refrigeration circuit, the evaporator coil plays a critical role. Part of its responsibility is creating the controlled pressure drop necessary for the refrigerant to change phase, the bulk of which occurs via the system’s metering device, such as a thermostatic expansion valve (TXV).

Read More

Topics:

Refrigerated Display Case,

Computer & Electronics Cooling,

HVAC,

Coils,

Efficiency,

Expertise,

Refrigerants

This article has been updated. It is accurate as of Feb. 8, 2022

For low-temperature hydronic systems, systems in which chillers and AHUs are located outdoors, or other equipment used in low-temperature processes, some form of glycol is a critical ingredient. It works to lower the fluid’s freezing temperature, enabling lower-temperature operation and preventing freezing.

Read More

Topics:

Food Storage & Processing,

Ground Support,

Coils,

Heat Exchangers,

Efficiency,

Expertise,

Reliability,

Engineering

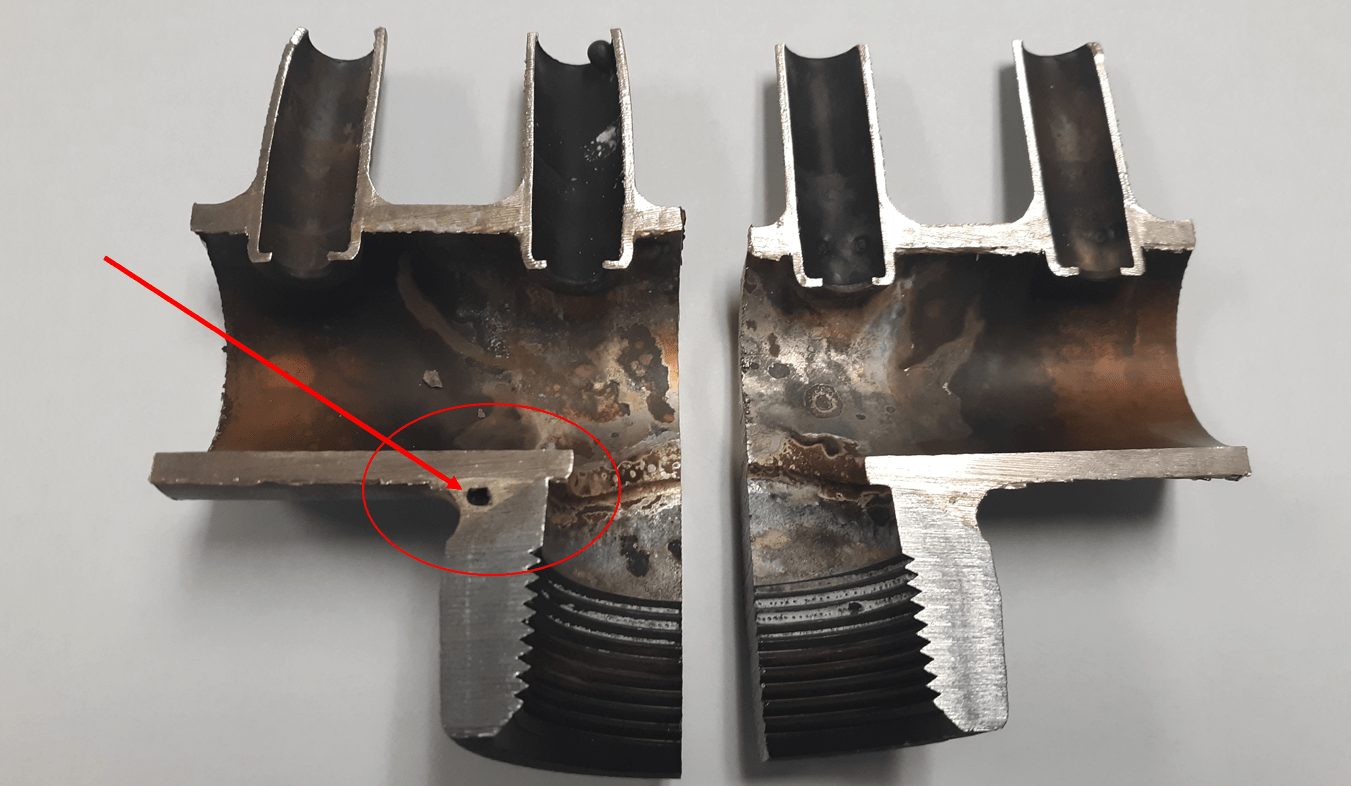

There are terrific braze joints, awful braze joints, and everything in between. Today, we’ll examine one type of defect that can have devastating effects on joint integrity – flux entrapment.

Read More

Topics:

Coils,

Heat Exchangers,

Expertise,

Quality

This article has been updated. It is accurate as of 9/23/20.

Heat exchangers used for different applications need different design features. For example, in industries like pulp and paper, lower fins per inch (FPI) are often included to reduce airside fouling and to make for easier cleaning. Other applications such as the military are often concerned with weight, which impacts material selection. For this post, we're going to focus on some unique design choices we often include when building heat exchangers for the refrigerated storage of potatoes, onions, beets and other vegetables.

Read More

Topics:

Food Storage & Processing,

Coils,

Heat Exchangers,

Quality,

Reliability