Hydronics systems? Football? While you may not hear those terms in the same breath every day, there’s actually a mind-blowing amount of design and engineering that help keep football field surfaces playable through the cold winter months.

First, some context

With this year’s big game being played in Tampa Bay, frozen ground won’t play a factor, but January's NFC championship game took place at the site of probably the most famous instance of frozen turf in history - historic Lambeau Field.

Read More

Topics:

Food Storage & Processing,

HVAC,

Expertise,

Reliability,

Engineering

As far as stages go, professional football's championship game is one of the biggest out there, and there’s a small army responsible for making sure everything goes off without a hitch. Behind that army of personnel is an even larger assemblage of vehicles, equipment, and other technology that help along the way – one of which is the heat exchanger.

Heat exchangers of all shapes, sizes, and functions play a part in the Great American Game – from down on the field to very high above it. So, we thought it’d be fun to list some that help to make the big game everything we know and love.

Read More

Topics:

Refrigerated Display Case,

Food Storage & Processing,

Ground Support,

Computer & Electronics Cooling,

HVAC,

Coils,

Efficiency,

Reliability

There are a number of industrial processes that require extremely cold temperatures – sometimes as cold as -150°F. For the equipment used in such applications, those low temperatures pose some unique challenges. In this post, we’ll detail some of the temperatures involved and outline some things to consider with regard to heat exchanger design and materials for low-temp applications.

Read More

Topics:

Food Storage & Processing,

Coils,

Heat Exchangers,

Expertise,

Reliability,

Engineering

Gas-tungsten arc welding (GTAW), or more commonly, Tungsten Inert Gas welding (TIG), is a method of arc welding named for the non-consumable tungsten electrode used during the process. TIG welding isn’t the best option in some industries, but as coil manufacturers, it makes sense for us.

Read More

Topics:

Gas Compression,

Military,

Food Storage & Processing,

Power Generation,

Heat Exchangers,

Nuclear Products,

Expertise,

Quality,

Reliability,

Engineering

This article has been updated. It is accurate as of Feb. 8, 2022

For low-temperature hydronic systems, systems in which chillers and AHUs are located outdoors, or other equipment used in low-temperature processes, some form of glycol is a critical ingredient. It works to lower the fluid’s freezing temperature, enabling lower-temperature operation and preventing freezing.

Read More

Topics:

Food Storage & Processing,

Ground Support,

Coils,

Heat Exchangers,

Efficiency,

Expertise,

Reliability,

Engineering

This article has been updated. It is accurate as of 9/23/20.

Heat exchangers used for different applications need different design features. For example, in industries like pulp and paper, lower fins per inch (FPI) are often included to reduce airside fouling and to make for easier cleaning. Other applications such as the military are often concerned with weight, which impacts material selection. For this post, we're going to focus on some unique design choices we often include when building heat exchangers for the refrigerated storage of potatoes, onions, beets and other vegetables.

Read More

Topics:

Food Storage & Processing,

Coils,

Heat Exchangers,

Quality,

Reliability

Around 2010, the first refrigeration systems operating on transcritical CO2 began cropping up in North American supermarkets. Since then, usage of transcritical CO2 systems has grown steadily and they’ve become viable options for places like supermarkets, food warehouses, and ice rinks, as more organizations move away from traditional HFC refrigerants. Natural refrigerant market accelerator Shecco estimates that transcritical CO2 systems grew from 140 in 2008 (all in Europe) to more than 35,000 systems worldwide today.

Read More

Topics:

Food Storage & Processing,

HVAC,

Expertise,

Engineering,

Refrigerants

Oftentimes, using stainless steel components seems like a simple solution to corrosion on coils. You may see fins or tubes or other parts of the system show signs of corrosion, and it seems that the best option is to change the coil to stainless steel, solving the corrosion problem permanently. While this seems like a simple solution to a significant problem in the HVAC, industrial, and commercial systems where coils are found, the answer to the question “should I make an all-stainless coil?” is far more complex.

Read More

Topics:

Gas Compression,

Refrigerated Display Case,

Food Storage & Processing,

Power Generation,

Heat Exchangers,

Expertise,

Engineering

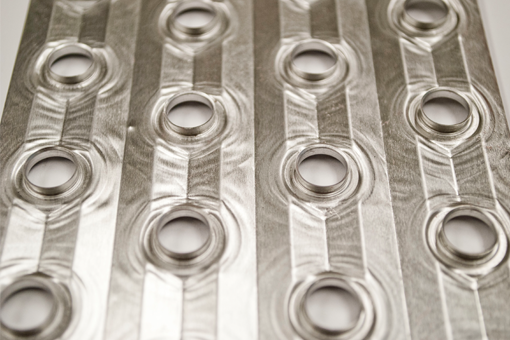

In plate fin heat exchangers, the fins themselves play a critical role. They provide the extended surface area needed to achieve effective heat transfer between a gas on the finside and a fluid on the tubeside.

Read More

Topics:

Gas Compression,

Refrigerated Display Case,

Food Storage & Processing,

Ground Support,

Computer & Electronics Cooling,

Power Generation,

HVAC,

Coils,

Efficiency,

Engineering

This article has been updated. It is accurate as of 9/23/20.

For commercial operations that rely on effective heat transfer, external corrosion of heat exchanger components is a major concern. When left unchecked, corrosion can significantly reduce a coil's effectiveness, but sometimes it’s difficult to know which anti-corrosion option best meets your needs.

Read More

Topics:

Refrigerated Display Case,

Food Storage & Processing,

HVAC,

Efficiency,

Reliability,

Engineering