In many of the industries we serve, heat exchangers made with copper tubes and aluminum fin are extremely popular, and very often, these materials are a terrific choice. But copper and aluminum aren’t suited for everything. At Super Radiator Coils, the needs of many of our customers often dictate that we explore and understand alternative materials.

Read More

Topics:

Gas Compression,

Military,

Power Generation,

Coils,

Heat Exchangers,

Nuclear Products,

Expertise,

Quality,

Engineering

In fin tube heat exchangers, the fluid (gas/water/glycol/refrigerant/etc.) circulating through the coil’s tubes is extremely important for the coil’s overall performance – it’s half the battle, along with airside heat transfer. The degree to which the fluid contacts the tube walls affects the coil’s performance and influences a system's overall efficiency – the more the fluid comes into contact with the tube wall, the better – and more economical – the heat transfer.

Read More

Topics:

Coils,

Heat Exchangers,

Efficiency,

Engineering

Around 2010, the first refrigeration systems operating on transcritical CO2 began cropping up in North American supermarkets. Since then, usage of transcritical CO2 systems has grown steadily and they’ve become viable options for places like supermarkets, food warehouses, and ice rinks, as more organizations move away from traditional HFC refrigerants. Natural refrigerant market accelerator Shecco estimates that transcritical CO2 systems grew from 140 in 2008 (all in Europe) to more than 35,000 systems worldwide today.

Read More

Topics:

Food Storage & Processing,

HVAC,

Expertise,

Engineering,

Refrigerants

Systems designed to cool air, whether for HVAC, industrial facilities, or manufacturing operations all have to address it. Failure to address it can lead to botched processes, reduced production, ruined equipment or uncomfortable building occupants. It can be expressed in percentage, lb./lb., wet bulb temperature, or other metrics. The silent “it” is humidity. Put simply, humidity is a measure of the amount of water vapor in the air, and while overlooking this simple measure can be costly, it can also be readily addressed during system design.

Like what you're reading? Subscribe to our blog and never miss a post!

Read More

Topics:

Coils,

Efficiency,

Expertise,

Engineering

Oftentimes, using stainless steel components seems like a simple solution to corrosion on coils. You may see fins or tubes or other parts of the system show signs of corrosion, and it seems that the best option is to change the coil to stainless steel, solving the corrosion problem permanently. While this seems like a simple solution to a significant problem in the HVAC, industrial, and commercial systems where coils are found, the answer to the question “should I make an all-stainless coil?” is far more complex.

Read More

Topics:

Gas Compression,

Refrigerated Display Case,

Food Storage & Processing,

Power Generation,

Heat Exchangers,

Expertise,

Engineering

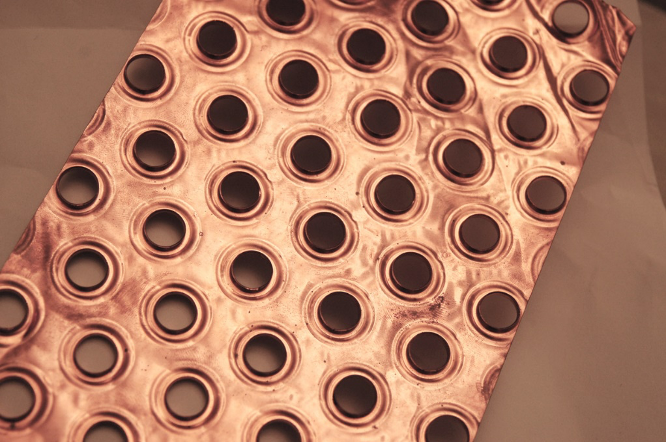

In plate fin heat exchangers, the fins themselves play a critical role. They provide the extended surface area needed to achieve effective heat transfer between a gas on the finside and a fluid on the tubeside.

Read More

Topics:

Gas Compression,

Refrigerated Display Case,

Food Storage & Processing,

Ground Support,

Computer & Electronics Cooling,

Power Generation,

HVAC,

Coils,

Efficiency,

Engineering

An 800MW 2x1 combined-cycle power plant in Alberta, Canada was experiencing consistent frost issues on anti-icing coils in their gas turbine inlet filter houses. The purpose behind these coils is to bring the temperature of the air up to just above the dew point, to prevent the condensation of water (which can cause serious damage through icing if introduced into the turbine.)

Read More

Topics:

Power Generation,

Expertise,

Engineering,

Turbine Inlet Air Cooling and Heating

This article has been updated. It is accurate as of 9/23/20.

For commercial operations that rely on effective heat transfer, external corrosion of heat exchanger components is a major concern. When left unchecked, corrosion can significantly reduce a coil's effectiveness, but sometimes it’s difficult to know which anti-corrosion option best meets your needs.

Read More

Topics:

Refrigerated Display Case,

Food Storage & Processing,

HVAC,

Efficiency,

Reliability,

Engineering

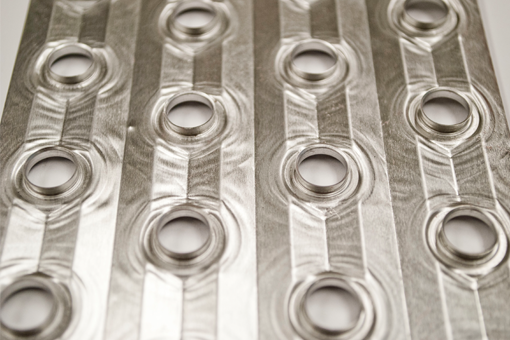

We get asked a lot of questions about the passivation of stainless steel welds. Oftentimes, customers want to know what passivation is. Others ask if it’s necessary. Given the number of factors that such a decision hinges on, Super Radiator wants customers to understand the benefits of passivation, and also understand what’s involved in the larger process of treating stainless steel surfaces.

Read More

Topics:

Food Storage & Processing,

Power Generation,

Heat Exchangers,

Nuclear Products,

Quality,

Engineering

Stainless, copper, E-coat, Heresite, or CuNi?

When Super Radiator Coils engineer coils for customers, materials are among our most important considerations. Things like applications, environments, and coil lifespan must all be factored in to the coil’s design. So too must price and industry standards, making material decisions all the more crucial.

Read More

Topics:

Heat Exchangers,

Expertise,

Quality,

Engineering