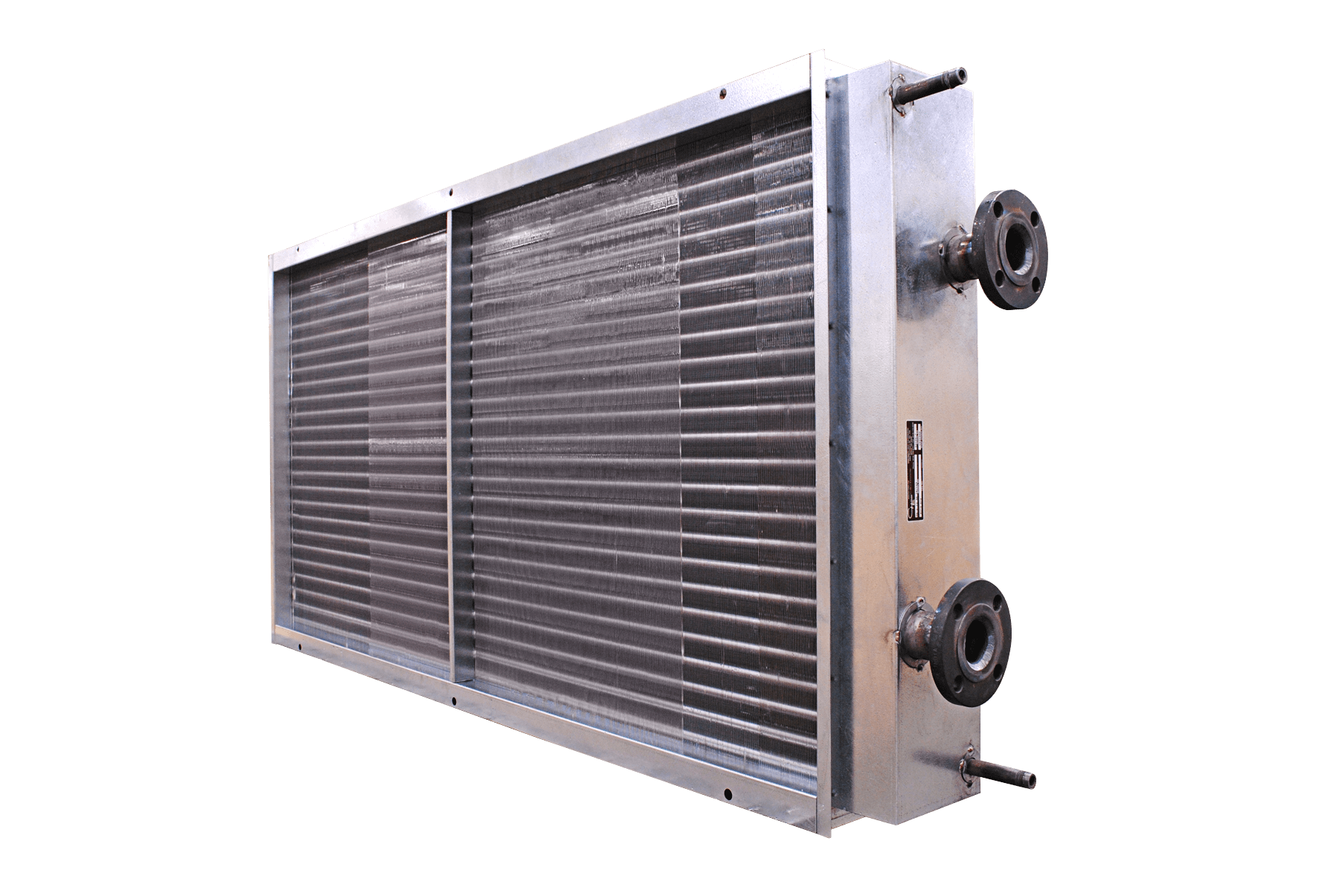

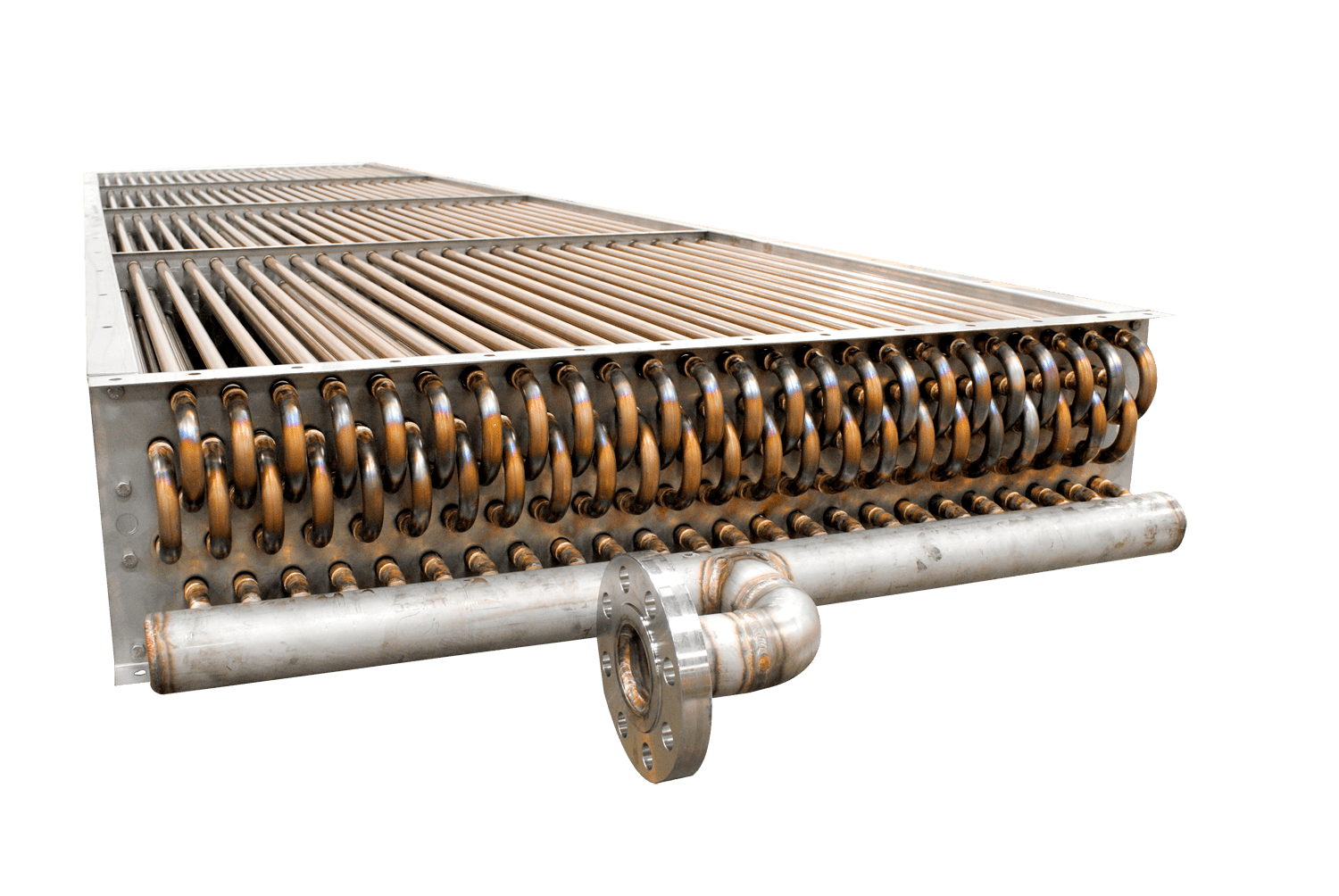

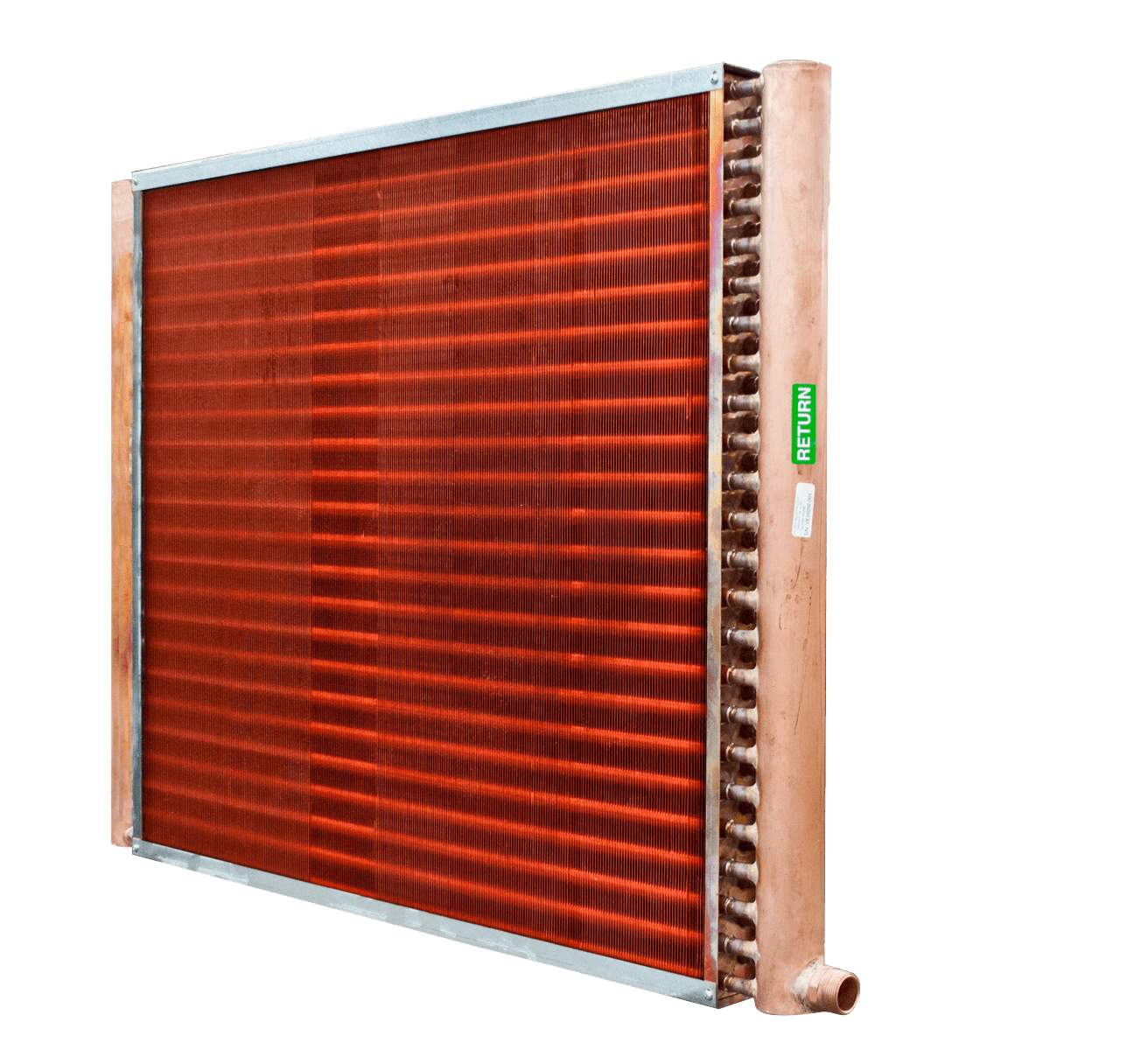

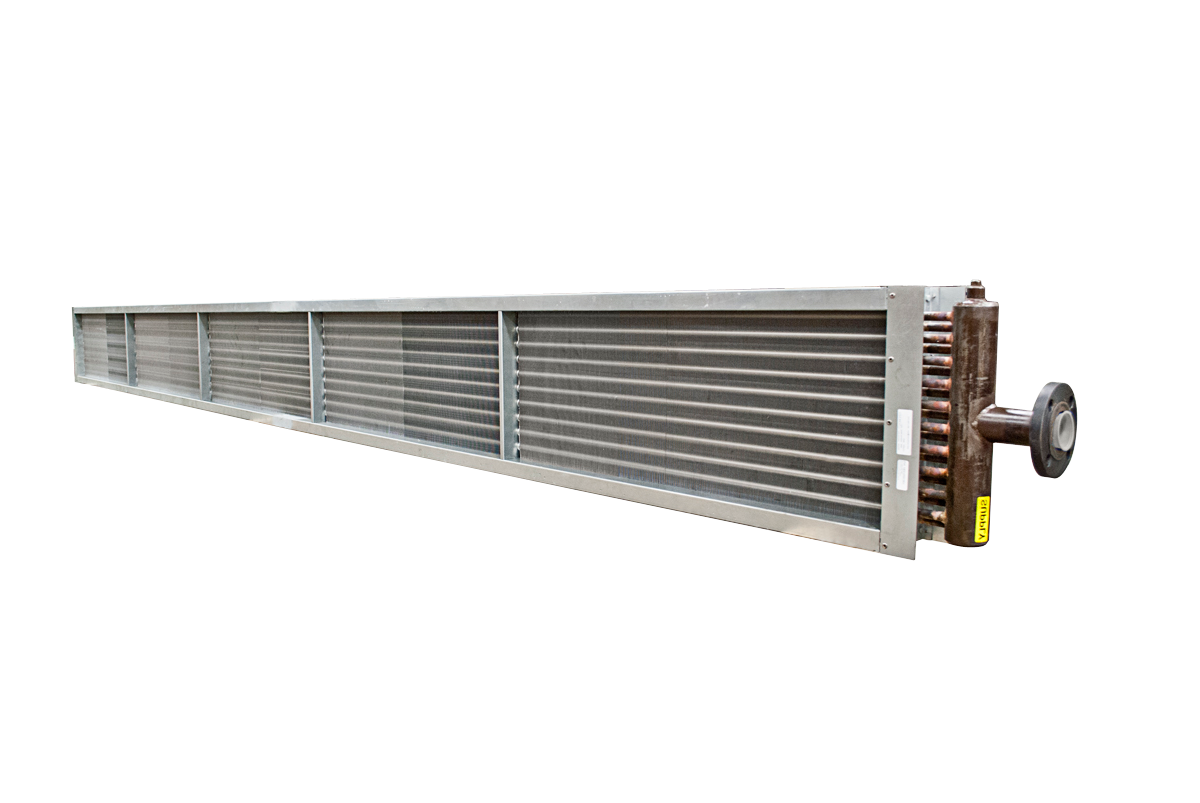

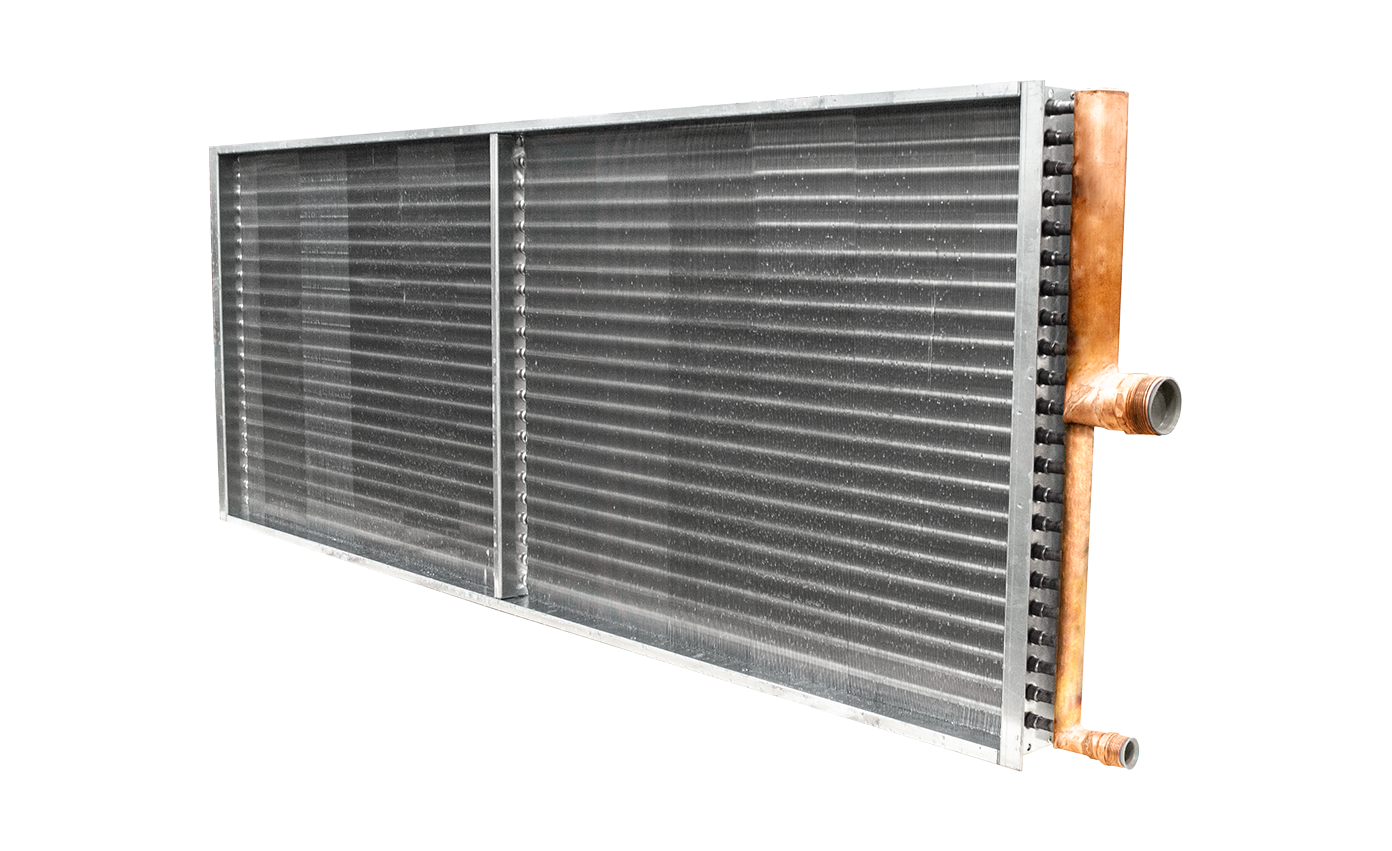

Steam Coils

Steam coils are designed and manufactured for applications ranging from commercial to industrial. Their primary function is to heat the air when steam is available.

Typically, these coils are built with thicker materials due to steam temperature/pressures, added chemicals, dissolved air in the steam and/or the high velocity of steam travelling through tube openings.

In order to get the most out of the steam coil design, all condensate must be removed. This can be achieved through a pitched design and/or ensuring that the steam has sufficient velocity. Without removal, users can expect decreased thermal performance or experience water hammer-type effects or coil failure.

Our steam coils are used in several industries, including food storage & processing, power generation, HVAC, and military.